The Design Process and Computational Fluid Dynamics (CFD)

by Bryan Baker, Naval Architect

by Bryan Baker, Naval ArchitectWorking at Farr Yacht Design has been an exciting and challenging experience for me. I began my career at FYD working on hull development via hydrodynamic research for BMW-Oracle Racing. Today, my primary role, unique to FYD, is developing and advancing our in-house Computational Fluid Dynamics (CFD). CFD is becoming a fairly common term in yacht design but for most sailors its function in the design process is still a bit of a mystery. The best way to explain the utility of CFD is to describe a typical research project and expand on its role.

Think of a typical research project as a filter (Fig. 1). The results from CFD/tank testing are filtered through a Velocity Prediction Program (VPP) to create polar data. The polar data is further filtered through a race model or weather model resulting in a single performance number. This filtering process reduces massive amounts of experimental data to just a single number, like the elapse time of the intended race course, from which an optimum design is chosen. Depending on the size of the research project, upwards of fifty variant designs will be subjected to the filtering process. Each variant is used to explore a specific region of the design space helping to determine the optimal shape.

Think of a typical research project as a filter (Fig. 1). The results from CFD/tank testing are filtered through a Velocity Prediction Program (VPP) to create polar data. The polar data is further filtered through a race model or weather model resulting in a single performance number. This filtering process reduces massive amounts of experimental data to just a single number, like the elapse time of the intended race course, from which an optimum design is chosen. Depending on the size of the research project, upwards of fifty variant designs will be subjected to the filtering process. Each variant is used to explore a specific region of the design space helping to determine the optimal shape.As shown above, the results of the filter are extremely reliant on quality of the test data. If there exists a substantial amount of error in the test results, then there is a very good probability that a sub-optimal design could be chosen. Thus any testing method requires meticulous execution and exhaustive validation.

In my experience, I have found that research is best executed by substantial automation of key configuration steps to avoid human errors. Pretty much let the computer do the grunt work and never key in the same quantity more than once. At FYD, a sophisticated suite of software has been developed to ensure consistency between research models. This software positions appendages while scaling volumes and moving weights to ensure each design is logically floating on its intended lines. The system also ensures realistic appendage geometry by further constraining foils to maintain realistic structural and/or hydrodynamic requirements.

In my experience, I have found that research is best executed by substantial automation of key configuration steps to avoid human errors. Pretty much let the computer do the grunt work and never key in the same quantity more than once. At FYD, a sophisticated suite of software has been developed to ensure consistency between research models. This software positions appendages while scaling volumes and moving weights to ensure each design is logically floating on its intended lines. The system also ensures realistic appendage geometry by further constraining foils to maintain realistic structural and/or hydrodynamic requirements.Test data is best validated by confirmation from two or more completely different sources. A well funded research project utilizes both tank testing and CFD techniques to ensure realistic results. Often, we use tank tests to confirm CFD data, but the validation of both techniques is independent of one another. In the tank, typically a model is tested at some fraction of the full scale design. Thus forces and moments recorded from the model must be scaled to a full scale prediction. Unfortunately, scaling is not often a trivial operation. Usually, many iterations of scaling forces and moments are required to produce realistic results. In general, these results are confirmed by subjective review of polar data from the VPP.

CFD is calibrated much differently than tank testing. The full scale geometry is often tested to avoid the before mentioned model scale effects. Thus validation is only conducted by changing the geometry that defines the problem, the boundary conditions that govern the problem, and/or conditionals that control the problem.

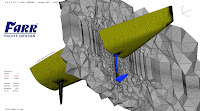

In CFD, the geometry that defines the problem is called the mesh or grid, (Fig. 2). The mesh is constructed of points or nodes at the intersections of lines or elements. These nodes can be thought of as the communicator telling the fluid equations about the yacht and the domain in which the yacht operates. If the mesh has too few nodes, then there is not enough communication between the fluid equations and geometry resulting in error. If the mesh has too many nodes, then the communication will take a long time. The key to meshing is communicating our intended geometry to the fluid equations whilst managing acceptable run times. As technology evolves and computers become faster, larger CFD meshes can be computed, yielding more accurate results with shorter run times. Given current computer technology and costs, we are able to compute CFD results more feasibly than conventional tank testing. A typical tank test could take more than a month considering model construction and number of test cases. A CFD project can happen as quickly as a week given ample resources.

In CFD, the geometry that defines the problem is called the mesh or grid, (Fig. 2). The mesh is constructed of points or nodes at the intersections of lines or elements. These nodes can be thought of as the communicator telling the fluid equations about the yacht and the domain in which the yacht operates. If the mesh has too few nodes, then there is not enough communication between the fluid equations and geometry resulting in error. If the mesh has too many nodes, then the communication will take a long time. The key to meshing is communicating our intended geometry to the fluid equations whilst managing acceptable run times. As technology evolves and computers become faster, larger CFD meshes can be computed, yielding more accurate results with shorter run times. Given current computer technology and costs, we are able to compute CFD results more feasibly than conventional tank testing. A typical tank test could take more than a month considering model construction and number of test cases. A CFD project can happen as quickly as a week given ample resources.Boundary conditions and conditionals are fundamental to validating CFD results. Most mathematicians would agree that defining appropriate boundary conditions is the most difficult step in solving numerical methods. For this reason, our CFD resources include both academic and commercial codes developed from vastly different boundary treatments. We work directly with universities and other organizations to remain on the forefront of new code development. We rely on only the most experienced fluid dynamics professionals who maintain a clear understanding of numerical error when tuning codes to produce the most convergent solutions.

In a typical CFD solution, we are able to compartmentalize features of the yacht and locally study there effects. For instance, we can directly compute the keel-fin’s lift contribution and compare its effects from one design to another. This is not only useful for determining the validity of a solution, but also understanding the relationships between components of the yacht for a more complete optimization of the entire package. The dillet region at the hull/keel-fin intersection is a good example of optimizing such relationship.

In a typical CFD solution, we are able to compartmentalize features of the yacht and locally study there effects. For instance, we can directly compute the keel-fin’s lift contribution and compare its effects from one design to another. This is not only useful for determining the validity of a solution, but also understanding the relationships between components of the yacht for a more complete optimization of the entire package. The dillet region at the hull/keel-fin intersection is a good example of optimizing such relationship.The single largest difference between tank testing and CFD is the ability to visualize the physics of the problem. Techniques exist to trace particles, capture the free surface profiles, and record pressure and shear information in tank testing, however such devices are fickle, setup is often ‘a priori’, and implementation is expensive. CFD offers a more complete picture of these physics by virtue of the equations being solved. As previously mentioned, the nodes of the mesh contain all the information necessary to visualize the fluid domain. The shape’s influence on the flow is easily compared using special plotting techniques. New concepts and ideas can be realized by looking at different operating conditions and comparing different designs.

In all, research of performance yachts hinges on good scientific practice and design experience. We still require more than one tool to accurately predict a yachts performance. We require the most talented experimental and theoretical hydrodynamic and aerodynamic professionals in the industry to ensure the very best test results.

-Bryan Baker, Naval Architect

.png)

2 comments:

Bryan - great article - thanks. I looking at the keel on my Farr designed Beneteau First 36.7, I notice that the aft portion of the keel is actually slightly concave in nature. Usually keels are slightly convex throughout. Is this a new development in keel shape? Was this a result of CFD design work? What is the effect on the yacht performance? Many thanks.

Hi,

My name is Pierre Orphanidis and I'm the editor of Valencia Sailing. I just discovered the FYD blog and some of the articles are extremely interesting.

Would it be possible to reproduce them on Valencia Sailing, with full credit OF COURSE?

Regards,

Pierre

Post a Comment